Fine-Sacks

Fine-Print has an extensive range of products that can be adapted for many functions. Our models feature large bagging capacity, between 7 kg and 50 kg, and can be produced in White, natural or BX Kraft Paper (mix or brown and white fibers).

| Food Products | Animal Feed | Seeds | Chemical Products | Ores | Civil Construction |

| Sugar, flour, rice, bran, farina, starch | Kaolin, bentonite, phylite, aluminum oxide | Cement, mortar and lime |

Printing Properties

Fine-Print offers its customers high technology in printing for industrial bags, excellently satisfying all design and printing quality demands. Each layout is developed according with the objectives and peculiarities of each customer.

- Flexographic Printing in up to 4 colors

Paper Bags Types

The definition of the ideal model of bag depends on how the bagging, storage and distribution by the end customer will be carried out. Presently, Fine-Print produces the following models:

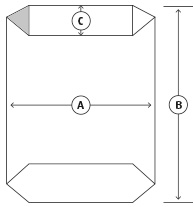

Pasted Valved Stepped End

Ideal for automatic, manual, rotating and stationary packing machines in high-speed. After filling, the valves close with the pressure of the product itself during the process.

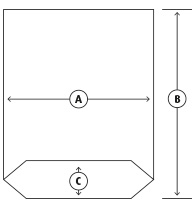

Open Mouth/flash cut bags with pasted bottom

Suitable for simple packing machines, allowing the introduction of plastic film in its interior, ensuring the protection of the product.

| Possible Sizes (cm) | |||||

| Face A | Length B | Valve C | |||

| Min. | Max. | Min. | Max. | Min. | Max. |

| 18 | 63,5 | 25 | 107 | 7 | 18 |

| Possible Sizes (cm) | |||||

| Face A | Length B | Bottom C | |||

| Min. | Max. | Min. | Max. | Min. | Max. |

| 18 | 63,5 | 25 | 107 | 7 | 18 |

Specification of Valve Bags

The production of valve bags may vary according to the characteristics of the product, bagging conditions, storage and the handling of paper bags.

For specific products, use an additional sheet of HDPE (High Density Polyethylene), or one of the sheets coated with polyethylene, which provide a better conservation of the bagged product.

- 1. APPLICATION OF 1 TO 4 PLIES

- 2. FROM 70 TO 120 G/M2

Valve Types

Valved, Paper Insert, Tuck in Sleeve, Ultrasonic, Polylocks, Double Trap, Reduced Tuck in Sleeve.